CONTACT US

CONTACT US

TALK TO US NOW

DESIGN & ANALYSIS TOOLS

- Variation Simulation Analysis

- Weld Distortion Analysis

- Virtual Prototyping & System Simulation

- Offline Programming

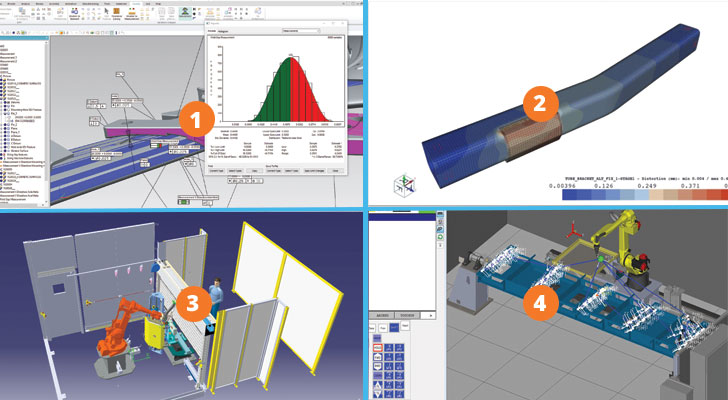

- Variation Simulation Analysis (VSA) increases the success of automation processes and increases productivity through collaboration and iteration of design process. Calculating predicted variabilities at critical interface areas in assembly and incorporating these results in production improves system performance and lowers overall costs.

- Weld Distortion Analysis (WDA) simulates welding of parts and components to predict material distortion during the production process. Material distortion negatively affects dimensional accuracy of parts increasing scrap, rework and the cost-per-part.

- Virtual Prototyping or System Simulation is conducted collaboratively with customers to create multiple digital proof-of-concepts to ensure that robotic system designs meet production requirements. Collaboration early in the process sets clear performance expectations for delivered production systems.

- Offline programming gets products to market faster by identifying automation inefficiencies to increase system uptime and throughput. Optimizing robotic programs is challenging in production settings as it disrupts normal operations that reduce productivity.

OPTIMIZE WELD

PROCESS & JOINT LOCATIONS

ELIMINATE POTENTIAL

REWORK & SCRAP

OPTIMIZE PROCESSES

SHORTEN PRODUCT

LAUNCH TIMELINE

Simulate Product And Process Variations in a Virtual Manufacturing Environment

Study Digital Prototypes & Analyze Process Capabilities

The Virtual Solutions Center provides an immersive environment to investigate and analyze automated solutions as designed visually to identify potential issues and gauge production effectiveness. Beginning with modeling the inputs of part geometries through fixturing, then simulating manufacturing to assess productivity, further analyzing results and measuring against design requirements, and finally identifying areas of improvement — these accurate simulations provide the opportunity to revise designs and optimize the process ahead of installation to maximize system effectiveness and lower overall costs.